Product Overview: 1、 Product OverviewThe pulsating vacuum dryer uses a vacuum system to extract air and moisture, creating a vacuum state in the inner cavity, reducing the boiling point of water, and accelerating the drying speed. Pulse type vacuum dryer belongs to static vacuum drying equipment. The material is pla

1、 Product Overview

The pulsating vacuum dryer uses a vacuum system to extract air and moisture, creating a vacuum state in the inner cavity, reducing the boiling point of water, and accelerating the drying speed. Pulse type vacuum dryer belongs to static vacuum drying equipment. The material is placed on a layer board inside a square vacuum dryer in a drying tray, and a heat medium is introduced into the layer board. The heat of the heat medium is transferred to the material through the drying tray for drying. The equipment consists of a drying tray, a shelf layer, a box, a vacuum system, a heating system, a pulse bubble system, a monitoring system, and valve pipelines.

2、 Product advantages

1. Greatly improve drying efficiency and shorten drying time by over 75%

2. Compared to a drying oven, it saves over 200% energy

3. Less equipment is required under the same production capacity, saving factory space.

4. Better product uniformity, better quality and color of dried products

5. The dried finished product is honeycomb shaped

6. High pressure gas pulse secondary bubble process

3、 Dry data analysis

1. Flat water temperature 60 ℃; Oven vacuum degree 4000PA --8000pa

2. 4000PA-8000PA; The boiling point of water is between 28-41 ℃

3. The latent heat of vaporization of water ranges from 2432.2 to 2402.3 kj/kg

4. 48 disc water pump 2.2kw centrifugal pump; Flow rate 11700L; Lift 28M;

5. Drying tray size: 550 * 420mm, height 60mm, loading 20-25mm. The material has a specific gravity of about 1.3, a solid content of 25-40%, and a water content of 3.6-4.5kg per plate after drying, with a material weight of 1.5-2.4kg

6. The output of 48 plates is between 72-115.2kg; Evaporated water 172-216kg

7. The water content of the flat plate shall not exceed 1/348 of the heated water tank. The water content of the flat plate shall be 18L/block and the total water content shall be 144L; Water tank 440L; Heating from 20 ℃ to 80 ℃ requires 110880kj to preheat in 1 hour; At least 30.8kw is required

8. Test data

48 discs: evaporation rate per hour: 216kg * 5h=43.2kg/h

Latent heat of vaporization: 43.2kg/h * 2432.2kj/kg=105071kj/h and 29.2kw

Heat medium: 11000KG * 60% * 4.2KJ/KG ·℃=27720kj/℃

The heat medium drops by 3.8 ℃, and the uniformity of the plate meets ± 3 ℃

The heating power should be 36kw

48 disks; Space of 3.2 cubic meters; Vacuum unit 150L/s

The water vapor density is 0.024kg/m ³ at 4000pa. Extraction is required every hour

To meet the extraction rate requirements of a 1800m ³ steam vacuum unit, a condenser must be added to reduce the load on the vacuum unit; The cooling capacity of the water cooling mechanism should be at least 36kw and 10p, with a water flow rate of 5m ³/h. The outlet temperature should be 5-30 ℃, and the refrigerant only needs to be heated by 5 ℃. Condenser heat dissipation area 3m ²

Technical parameters and configuration list of pulsating vacuum dryer (single unit)

1. Technical parameters

Serial Number | Project | Parameter | Notes | |

1.1 comprehensive | ||||

Whole machine structure | Rectangular mobile door | |||

Specification and model | MZG-48 | Standard configuration | 1 unit | |

External dimensions | 1940*1700*1910mm | Length * Width * Height | 1 unit | |

Internal cavity size | 1290*1330*1410mm | Length * Width * Height | 1 unit | |

Layer | 890x1150x30mm | Length x Width x Height | 1 piece/8 pieces in total | |

Board layer spacing | ≤115mm | Net distance between each layer | Design according to the characteristics of the material | |

Drying tray | 550x420x60mm | Length x Width x Height | 1 piece/48 pieces | |

Rated production capacity | 72~115.2kg (wet) | Each drying dish ****** should not exceed a capacity of 25mm | Related to the specific gravity and characteristics of the material | |

Rated power | 11.9KW | Vacuum unit 9.7KW | Assembly | |

Opening direction | According to customer requirements | |||

2. Equipment Configuration Table

| Serial Number | Name | Model/Specifications/Material | Number | Manufacturer |

2.1 main box | ||||

Outer sealing plate | SUS304 stainless steel 1.5mm thick brushed plate | 1 set | Wuxi Daming | |

Reinforcing | Q235 | 1 set | Nanjing Kaiou | |

Jacket | SUS304 stainless steel | 1 set | Nanjing Kaiou | |

XPS | 80mm aluminum silicate | 1 set | Nanjing | |

inner wall | SUS304 stainless steel 8mm thick | 1 set | Wuxi Daming | |

Outer seal of the box door | SUS304 stainless steel 3mm thick brushed plate | 1 set | Wuxi Daming | |

Inner wall of box door | SUS304 stainless steel 8mm thick | 1 set | Wuxi Daming | |

Door mirror | Front ∅ 200 mm; Rear ∅ 160mm | 3 pieces | Nanjing Kaiou | |

Door sealing strip | Medical grade silicone rubber | 1 set | Jiangsu | |

Detachable interior car | SUS304 | 1 vehicle | Nanjing Kaiou | |

External car | SUS304 | 1 vehicle | Nanjing Kaiou | |

Layer | SUS304 stainless steel 5mm | 8 yuan | Nanjing Kaiou | |

baking pan | SUS304 stainless steel 2mm | 48 pieces | Nanjing Kaiou | |

wired hose | SUS304 stainless steel | 1 set | Wenzhou | |

2.2 Box mouth | ||||

nozzle | SUS304 | 1 set | Nanjing Kaiou | |

2.3 Indoor induction system | ||||

Internal pressure transmitter | M12 | 1 piece | Danvers | |

Jacketed pressure transmitter | M12 | 1 piece | Danvers | |

Material temperature probe | Pt-100 thermistor | 1 piece | Jiumao | |

Indoor temperature | Pt-100 thermistor | 1 piece | Jiumao | |

Hot water temperature probe | Pt-100 thermistor | 1 piece | chint | |

temperature control | Pt-100 thermistor | 1 piece | chint | |

2.4 Pulse and Bubble Breaking System | ||||

Pulse pipeline | SUS304 | 1 set | Nanjing Kaiou | |

Pulse valve | SUS304 | 1 set | Nanjing Kaiou | |

Bubble breaking device | SUS304 | 1 set | Nanjing Kaiou | |

2.5 hot water | ||||

Hot water tank/steam heating | 400L | 1 unit | Nanjing Kaiou | |

Connecting rod float level gauge | DN25 (L-400) quick connect | 1 piece | Shanghai Sipai Electronics | |

Hot water circulation ring pump | 2.2KW | 1 piece | GRUNDFOS | |

control | Assembly | 1 set | Nanjing Kaiou | |

2.6 vacuum system | ||||

vacuum unit | Vacuum unit 9.7kw | 1 group | Zibo Boshan | |

surface air cooler | 304 material, 2 square meters | 1 unit | Nanjing Kaiou | |

buffer tank | 304 material 150L | 1 unit | Nanjing Kaiou | |

2.7 Other auxiliary | ||||

air filter | DN20 | 1 piece | Wenzhou | |

DN25 | 1 piece | Wenzhou | ||

pipe | AISI 304 | 1 set | Nanjing Kaiou | |

2.8 control valve | ||||

Pneumatic double acting ball valve | DN20 quick connect type | 1 piece | Wenzhou | |

check valve | DN25 quick connect type | 1 piece | Wenzhou | |

DN40 quick connect, flat main water pipe | 1 piece | Wenzhou | ||

drain valve | DN25 quick connect type, jacket | 1 piece | Shanghai | |

DN25 flange type, hot water tank | 1 piece | Shanghai | ||

Safety valve (0.15MP) | DN20 external thread, hot water tank and jacket | 2 pieces | Tianzheng Valve | |

Manual ball valve | DN40 quick connect, flat main water pipe | 2 pieces | Wenzhou | |

DN25 quick connect type | 4 pieces | Wenzhou | ||

DN15 quick connect, balanced box pressure | 1 piece | Wenzhou | ||

Pneumatic angle seat valve | DN25 quick connect type | 4 pieces | Wenzhou | |

DN25 quick connect type | 2 pieces | Wenzhou | ||

DN25 flange type, hot water tank and jacket inlet | 1 piece | Wenzhou | ||

DN65 flange type, chiller inlet | 1 piece | Wenzhou | ||

DN40 quick connect type | 1 piece | Wenzhou | ||

DN40 quick connect type | 1 piece | Wenzhou | ||

DN15 quick connect type, balance box pressure adjustment vent volume | 1 piece | Wenzhou | ||

2.9 Control system | ||||

PLC | SR40 | 1 piece | Siemens | |

Touch Screen | SMART 700 IE V3 | 1 piece | Siemens | |

Micro printer | WH-E361Z200 | 1 set | Beijing Bright | |

Low Voltage Apparatus | Main electrical appliances | 1 set | Schneider | |

Software system | 1 set | Nanjing Kaiou | ||

Electrical Appliance List

Name | Model Remarks | Manufacturer | Number |

Circuit breaker | IC65N D4P 50A | Schneider | 1 |

IC65N C1P 10A | Schneider | 1 | |

AC contactor | LC1E0910 M5N | Schneider | 5 |

LC1E1810 M5N | Schneider | 1 | |

Thermal relay | LRE07N | Schneider | 2 |

LRE10N | Schneider | 2 | |

LRE21N | Schneider | 1 | |

Intermediate relay | RXM2LB2BD | Schneider | 1 |

RXM2LB2P7 | Schneider | 3 | |

Electric cabinet fan | ZL-803 (Equipped with fan 12038/AC220V) | Outsourcing | 1 |

Micro printer | WH-E361Z200 | Brilliant | 1 |

Programmable controller | Siemens SR40 | Siemens | 1 |

Touch Screen | SMART 700 IE V3 | Siemens | 1 |

module | Siemens EM AR04 | Siemens | 1 |

Siemens EM AE04 | Siemens | 1 | |

Siemens SB CM01 | Siemens | 1 | |

Switch power supply | S-25T-24 | Mingwei | 1 |

Switch power supply | S-25T-5 | Mingwei | 1 |

Emergency stop switch | NP2-NS542 | Schneider | 1 |

Buzzer | AD56-22SM AC220V | Schneider | 1 |

Proximity switch | LJ12A4 AC220V normally open | Schneider | 2 |

Pressure transmitter | Danvers(-1,3BAR) | Danvers | 2 |

Pneumatic components | 3V210-08 AC220V(normally closed) | Outsourcing | 12 |

Utility

Serial Number | Name | Require | Consumption |

1 | Use water inside the shelf | ≦3.6µs/cm(10℃),≦4.3µs/cm(20℃),≤5.1µs/cm(25℃) | Recycling~200L |

2 | Clean compressed air | 0.5~0.8Mpa | 200-400L/min |

3 | Industrial steam | Jacket ≤0.1Mpa | ~40 Kg/h |

Water tank ≤0.4Mpa | ~10 Kg/h | ||

4 | Cooling water for water ring vacuum pump | Water supply temperature/pressure/water hardness 10-15°C;0.4-1.0Mpa;<8° | 0.4-1.2 m3/h |

5 | Roots pump cooling water | Cooling water | 0.2-0.6m³/h |

6 | Total power | AC three-phase five wire 380V | 11.9KW |

7 | Condenser water | ≦3.6µs/cm(10℃),≦4.3µs/cm(20℃),≤5.1µs/cm(25℃) | Recycling~20L |

Note: The cooling water used in the condenser is cooled by a refrigeration unit to ≤ 10 ℃ and circulated for use.

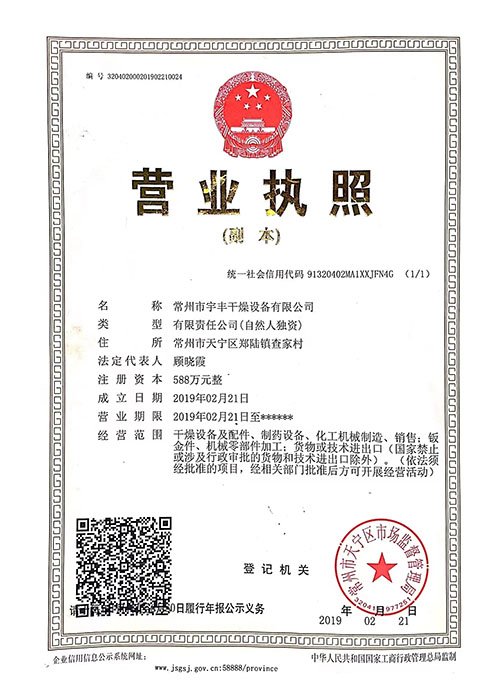

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13