Product Overview: Summary: The disc continuous dryer is a good conductive continuous drying equipment, and its unique structure and working principle determine that it has high thermal efficiencyCategory: Disc drying machineDetailed description:Overview The disc continuous dryer is a good conductive continuous drying

Summary: The disc continuous dryer is a good conductive continuous drying equipment, and its unique structure and working principle determine that it has high thermal efficiency

Category: Disc drying machine

Detailed description:

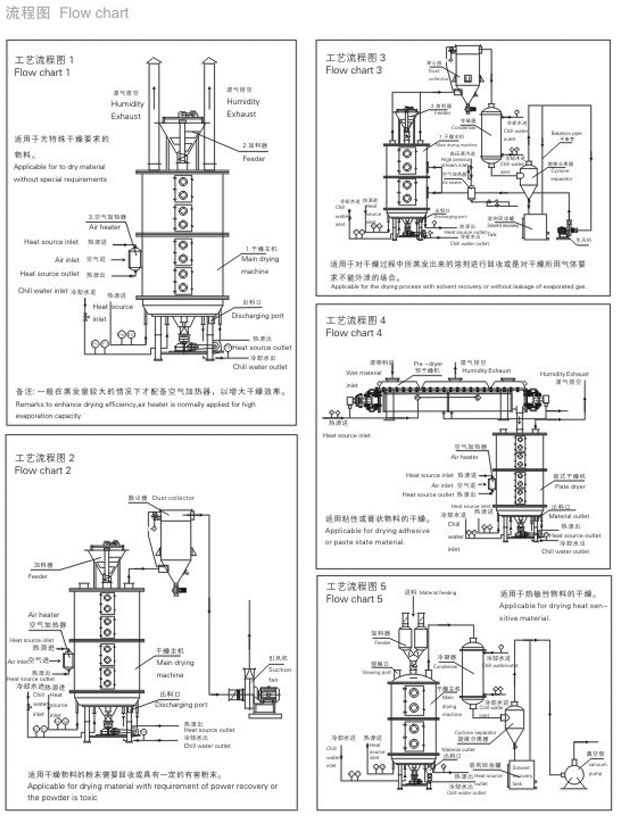

Overview The disc continuous dryer is a good conductive continuous drying equipment. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment. Widely applicable to drying operations in industries such as chemical, pharmaceutical, pesticide, food, feed, and agricultural and sideline product processing. Highly praised in practical applications across various industries. It can be divided into three types: atmospheric pressure, sealed, and vacuum; Various specifications such as 1200, 1500, 2200, 3000, etc; A (carbon steel), B (stainless steel for the contact material part), and C are made of three materials (stainless steel for the steam pipeline, main shaft, and support, and stainless steel for the cylinder and top cover lining) on the basis of B, with a drying area of 4-180m2. There are hundreds of models of series products available, and supporting auxiliary equipment can be provided to meet the drying needs of users for various materials.

The disc continuous dryer is a good conductive continuous drying equipment. Its unique structure and working principle determine that it has the characteristics of high thermal efficiency, low energy consumption, small footprint, simple configuration, convenient operation and control, and good operating environment. Widely applicable to drying operations in industries such as chemical, pharmaceutical, pesticide, food, feed, and agricultural and sideline product processing. Highly praised in practical applications across various industries. It can be divided into three types: atmospheric pressure, sealed, and vacuum; Various specifications such as 1200, 1500, 2200, 3000, etc; A (carbon steel), B (stainless steel for the contact material part), and C are made of three materials (stainless steel for the steam pipeline, main shaft, and support, and stainless steel for the cylinder and top cover lining) on the basis of B, with a drying area of 4-180m2. There are hundreds of models of series products available, and supporting auxiliary equipment can be provided to meet the drying needs of users for various materials.

Characteristic:

(1) Easy regulation and strong applicability

1.By adjusting the thickness of the material layer, spindle speed, number of rake arms, rake blade type and size, the drying process can be achieved.

2.Each layer of the drying tray can be filled with hot or cold medium to heat or cool the material, ensuring uniform heating and accurate temperature control.

3.The residence time of materials can be accurately adjusted.

4.The material has a single flow direction, no backmixing phenomenon, uniform drying, stable quality, and does not require further mixing.

(2) Simple and easy to operate

1.The operation of driving and parking the dryer is very simple.

2.After stopping the feeding, the rake blades that transport the material can quickly empty the material inside the dryer.

3.Through the special large-sized inspection door mirror, the equipment can be carefully cleaned and observed inside.

(3) Low energy consumption

1.The material layer is very thin, the spindle speed is low, and the material conveying system requires less power and consumes less electricity.

2.Drying with conductive heat results in high thermal efficiency and low energy consumption.

(4) Good operating environment, recyclable solvents, and dust emissions meet requirements

1.Atmospheric pressure type: Due to the low airflow velocity and low humidity distribution inside the equipment, it is difficult for dust to float to the top of the equipment. Therefore, the exhaust gas discharged from the top humidity outlet contains almost no dust.

2.Sealed type: equipped with a solvent recovery device, which can easily recover organic solvents in wet gases. The solvent recovery device is simple and has a high recovery rate. For flammable, explosive, toxic, and easily oxidizable materials, nitrogen can be used as a carrier gas for closed-loop circulation to ensure safe operation. Specially suitable for drying flammable, explosive, and toxic materials.

3.Vacuum type: A disc dryer operated in a vacuum state, particularly suitable for drying heat sensitive materials.

(5) Easy installation and small footprint

1.The dryer is shipped as a whole and only needs to be lifted into place for easy installation and positioning.

2.Due to the layered arrangement and vertical installation of the drying tray, even if the drying area is large, the footprint is also very small.

Application:

Drying, pyrolysis, calcination, cooling, reaction, sublimation

(1) Organic chemical products

(2) Inorganic chemical products

(3) Medicine and food

(4) Feed and fertilizer

Technical features:

(1) Drying dish

1.Design pressure: generally 0.4MPa, up to 1.6MPa.

2.Usage pressure: generally ≤ 0.4MPa, up to 1.6MPa.

3.Heating medium: Steam, hot water, heat transfer oil. When the temperature of the drying disc is 100 ℃, use hot water for heating. When the temperature is between 100 ℃ and 150 ℃, use saturated steam or superheated steam with a pressure of ≤ 0.4MPa for heating. When the temperature is between 150 ℃ and 320 ℃, use heat transfer oil for heating.

(2) Material conveying system

1.Spindle speed: 1-10 RPM, electromagnetic or variable frequency stepless speed regulation.

2.Rake arm: There are 2-8 rake arms fixed on the main shaft on each layer of the drying disc.

3.Rake blade: Twisted onto the rake arm, it can float up and down with the disc surface to maintain contact, and has various forms.

4.Rolling: For materials that are prone to clumping and need to be crushed, adding rolling at appropriate positions can enhance heat transfer and drying processes.

(3) Shell

There are three types: atmospheric pressure, sealed, and vacuum

1.Atmospheric pressure type: cylindrical or octagonal prism type, with two types of structures: integral and split. The main pipeline for the inlet and outlet of the heating medium can be located inside or outside the shell.

2.Sealed type: a cylindrical shell that can withstand an internal pressure of 5KPa. The main inlet and outlet pipes for the heating medium can be located inside or outside the shell.

3.Vacuum type: cylindrical shell with a design pressure of -0.096Mpa, and the main inlet and outlet pipelines of the heating medium are located inside the shell.

(4) Air heater

Generally used when configuring induced draft fans to prevent humid ambient air from entering the main unit and affecting the drying effect.

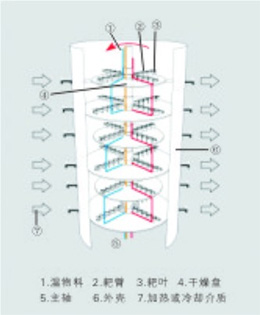

Principle:

Wet materials are continuously added to the upper layer drying disc of the dryer from the feeder, and the rake arm with rake blades rotates to continuously flip the materials. The material flows along an exponential spiral over the surface of the drying disc, and the material on the small drying disc is transferred to the outer edge. The material on the large drying disc moves inward and falls into the next layer of small drying disc from the middle discharge port. The drying plates of different sizes are arranged alternately up and down, allowing the material to flow continuously through the entire dryer. A hollow drying tray is filled with heating medium, which includes saturated steam, hot water, and thermal oil. The heating medium enters from one end of the drying tray and exits from the other end. The dried material falls from the subsequent drying tray to the bottom layer of the shell, and is then transferred by the rake blades to the discharge port for discharge. Wet steam escapes from the material and is discharged through the exhaust port located on the top cover. The wet steam of the vacuum disc dryer is extracted through the vacuum pump port located on the top cover. Dry materials discharged from the bottom layer can be directly packaged. By adding auxiliary equipment such as fin heaters, solvent recovery condensers, bag filters, dry material mixing mechanisms, and induced draft fans, the production capacity of drying can be improved. Drying paste like and heat sensitive materials can facilitate solvent recovery and enable pyrolysis and reaction operations.

Technical parameter table:

| Specifications | Outside diameter(mm) | Height(mm) | Drying area(m2) | Power(KW) | Specifications | Outside diameter(mm) | Height(mm) | Drying area (m2) | Power(KW) |

| 1200/4 | 1850 | 2608 | 3.3 | 1.1 | 2200/18 | 2900 | 5782 | 55.4 | 5.5 |

| 1200/6 | 3028 | 4.9 | 2200/20 | 6202 | 61.6 | ||||

| 1200/8 | 3448 | 6.6 | 1.5 | 2200/22 | 6622 | 67.7 | 7.5 | ||

| 1200/10 | 3868 | 8.2 | 2200/24 | 7042 | 73.9 | ||||

| 1200/12 | 4288 | 9.9 | 2200/26 | 7462 | 80.0 | ||||

| 1500/6 | 2100 | 3022 | 8.0 | 2.2 | 3000/8 | 3800 | 4050 | 48 | 11 |

| 1500/8 | 3442 | 10.7 | 3000/10 | 4650 | 60 | ||||

| 1500/10 | 3862 | 13.4 | 3000/12 | 5250 | 72 | ||||

| 1500/12 | 4282 | 16.1 | 3.0 | 3000/14 | 5850 | 84 | |||

| 1500/14 | 4702 | 18.8 | 3000/16 | 6450 | 96 | ||||

| 1500/16 | 5122 | 21.5 | 3000/18 | 7050 | 108 | 13 | |||

| 2200/6 | 2900 | 3262 | 18.5 | 3.0 | 3000/20 | 7650 | 120 | ||

| 2200/8 | 3682 | 24.6 | 3000/22 | 8250 | 132 | ||||

| 2200/10 | 4102 | 30.8 | 3000/24 | 8850 | 144 | ||||

| 2200/12 | 4522 | 36.9 | 4.0 | 3000/26 | 9450 | 156 | 15 | ||

| 2200/14 | 4942 | 43.1 | 3000/28 | 10050 | 168 | ||||

| 2200/16 | 5362 | 49.3 | 5.5 | 3000/30 | 10650 | 180 |

Note: Some parameters may be adjusted according to different materials during design, and the design shall prevail

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13