Product Overview: Description: DW series multi-layer belt dryer is a continuous drying equipment used in batch productionCategory: Belt dryerDetailed description:Product Introduction:The DW series multi-layer belt dryer is a continuous drying equipment used in mass production, used for drying sheet, strip, and granul

Description: DW series multi-layer belt dryer is a continuous drying equipment used in batch production

Category: Belt dryer

Detailed description:

Product Introduction:

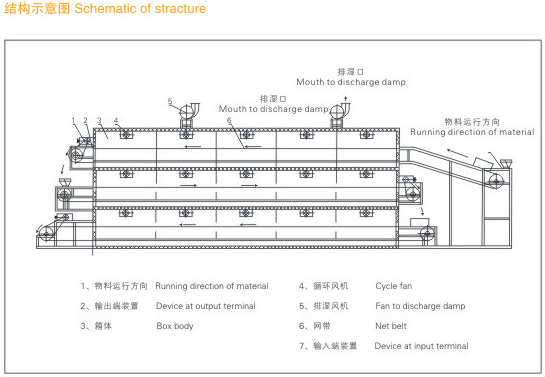

The DW series multi-layer belt dryer is a continuous drying equipment used in mass production, used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for dehydrated vegetables, catalysts, traditional Chinese medicine decoction pieces, and other materials with high moisture content and temperature requirements; This series of dryers has the advantages of fast drying speed, high evaporation intensity, and good product quality. For dehydrated cake like paste materials, they need to be granulated or made into strips before drying.

Overview:

The DW series multi-layer belt dryer is suitable for large-scale production of difficult to dry materials with low drying rates. The equipment has a compact structure, small footprint, simple operation, easy maintenance, and stable operation. Different forms of hot air circulation drying can be designed according to the drying characteristics of materials, which is an extension and improvement of hot air circulation ovens, widely used in metallurgical additives, chemical industry, food, packaging and other fields. With the advancement of enterprise technology and the improvement of product technology content, multi-layer belt dryers have the ability to meet large-scale production, diversification, centralized control, and continuous production needs. It has the advantages of energy saving and easy management.

Technical parameter table:

Model | DW3-1.2-8 | DW3-1.2-10 | DW3-1.6-8 | DW3-1.6-10 | DW3-2-8 | DW3-2-10 | ||

Number of units | 4X3 | 5X3 | 4X3 | 5X3 | 4X3 | 5X3 | ||

Drying section length m | 24 | 30 | 24 | 30 | 24 | 30 | ||

Laying thickness mm | 10-80 | |||||||

Usage temperature ℃ | 50~140 | |||||||

Steam pressure Mpa | 0.2~0.8 | |||||||

Steam consumption kg/h | 360-600 | 420-720 | 450-840 | 480-960 | 480-960 | 630-1350 | ||

Heat Exchange Area m2 | 816 | 1020 | 1056 | 1320 | 1344 | 1680 | ||

Dry strength kgH2O/h | 150-450 | 220-550 | 240-600 | 280-750 | 280-750 | 350-900 | ||

Total power of the internal unit KW | 30.8 | 37.4 | 42 | 51 | 56 | 68 | ||

Total power of external unit KW | 35.3 | 41.9 | 46.5 | 55.5 | 60.5 | 72.5 | ||

External dimensions m | 9.77X2.2X4.5 | 11.77X2.2X4.5 | 9.77X2.6X4.5 | 11.77X2.6X4.7 | 9.77X3.06X4.9 | 11.77X3.06X4.9 | ||

Total weight kg | 4800X3 | 5780X3 | 5400X3 | 6550X3 | 6350X3 | 7800X3 | ||

Note: For drying temperatures between 250~350 ℃, our company can make special designs based on actual materials. | ||||||||

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13