Product Overview: In terms of drying, due to the fact that the main component of chicken essence is derived from monosodium glutamate, which becomes the focus at temperatures above 120 ℃, monosodium glutamate is harmful to the human body after consumption. Therefore, when drying chicken essence, the temperature in the drying chamber needs to be controlled between 95 ℃ and 115 ℃ in order to fully utilize its nutritional value.

Description: The production process of chicken essence is as follows: Grain (wheat, corn, soybean) - MSG semi-finished product

Description: The production process of chicken essence is as follows: Grain (wheat, corn, soybean) - MSG semi-finished product

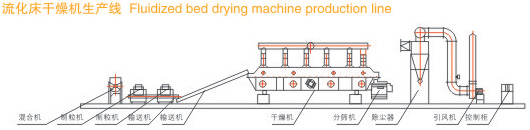

Category: Fluidized bed dryer

Detailed description:

Overview:

The production process of chicken essence is as follows: grain (wheat, corn, soybean) - MSG semi-finished product (monosodium glutamate) mixed with a small amount of other auxiliary materials such as chicken powder - granulation - drying - screening - packaging - inspection - finished product - storage. To obtain chicken essence products with excellent color, aroma, and appearance; The selection of auxiliary materials is crucial. The quality of semi-finished products such as monosodium glutamate (MSG) and oil tires plays a decisive role in the production of chicken essence. In terms of drying, due to the fact that the main component of chicken essence is derived from monosodium glutamate, which becomes the focus at temperatures above 120 ℃, monosodium glutamate is harmful to the human body after consumption. Therefore, when drying chicken essence, the temperature in the drying chamber needs to be controlled between 95 ℃ and 115 ℃ in order to fully utilize its nutritional value.

Our company has been dedicated to the research and development of production line equipment for chicken essence and chicken powder for many years. So far, we have developed multiple complete sets of production line equipment for chicken essence and chicken powder with different processes, all of which are made of stainless steel to meet the needs of users for QS certification. Our company's chicken essence and powder production line equipment has been used by multiple top ten chicken essence manufacturers in China, as well as manufacturers with large sales in the East China region.

Drying process description:

Our company has made significant improvements to the conventional vibrating fluidized bed dryer to meet the process requirements of chicken essence drying production. It has been applied in multiple chicken essence manufacturers and has received high praise from users.

Chicken essence has a certain degree of viscosity and is prone to sticking to the bed surface of the dryer, making drying impossible. Our company has taken various measures to solve this problem. After the squeezing and granulation of chicken essence, the surface moisture is relatively high. Our company's fluidized bed stage adopts low-temperature and high air volume pre drying to rapidly reduce the surface moisture of chicken essence, and at the same time, the surface viscosity is also reduced. The second stage of the fluidized bed adopts medium temperature and high air flow drying to further reduce the surface moisture of chicken essence. The third stage of the fluidized bed adopts medium temperature conventional air flow drying to ensure sufficient residence time of chicken essence in the fluidized bed for effective drying. The fourth section of the fluidized bed adopts high air flow cooling, which facilitates the direct packaging of chicken essence after screening. In summary, in order to meet the process requirements of chicken essence at different stages, there are corresponding design specifications for the opening rate, opening direction, and fan selection of the bed surface.

To improve the fluidization effect and operational reliability of the fluidized bed during chicken essence drying, our company has increased the volume of the boiling chamber in the fluidized bed produced, and the main engine adopts a frame structure.

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13