Description: Internal heating fluidized bed dryer is developed on the basis of conventional fluidized bed drying and indirect heating drying

Category: Fluidized bed dryer

Detailed description:

Overview

Internal heating fluidized bed dryer is a new drying technology developed on the basis of conventional fluidized bed drying and indirect heating drying. Immerse the heat exchanger in the fluidized drying material, and the heat required for material dehydration is provided by the tubular heat exchanger and the hot air for fluidization, which can meet the requirements of material fluidized drying with a small air volume. Due to the fact that most of the heat is provided by the built-in heat exchanger, hot air is mainly used as the power medium to ensure normal fluidization, which greatly reduces the amount of hot air required compared to conventional fluidized bed dryers, and greatly reduces power consumption and exhaust heat loss.

Suitable materials:

Hydrogenated amine, ammonium nitrate, calcium chloride, calcium formate, calcium gluconate, calcium sulfate, cellulose derivatives, diammonium phosphate, dicalcium phosphate, granular fertilizers, hydroquinone, iron sulfate, ethylene, propylene, polystyrene, potassium carbonate, potassium chloride, potassium nitrate, potassium phosphate, sodium potassium tartrate, sodium sulfate, polyvinyl chloride, sodium bicarbonate, sodium bromide, sodium formate, sodium perborate, sodium sulfate, tartaric acid, terephthalic acid, urea, vitamins. Barium sulfate, magnesium sulfate, zinc sulfate, aluminum sulfate, nickel sulfate, ammonium sulfate, table salt, sodium fluoride, titanium, potassium bromide, ammonium bromide, sodium carbonate, basic nickel carbonate, basic zinc carbonate, basic chromium carbonate, calcium carbonate, sodium metasilicate, potassium acetate, sodium benzoate, acrylic aldehyde monomer, polyacrylaldehyde amine, nickel 1010, polypropylene resin, polyester chips, polytetrafluoroethylene, acylaldehyde resin, tetracycline, tetracycline, humic acid, sodium humate, lysine.

Feature

● The cost of energy-saving sports is low.

● The cost of energy-saving sports is low.

● Low dry air volume and low system power consumption.

● High drying intensity, small equipment volume, and small system footprint.

● High operational flexibility and stable system operation.

● Special air distribution board can prevent material leakage and facilitate the discharge of large particles.

● Adopting two-stage dust removal can meet environmental emission requirements.

Technical parameter table:

| Model | Fluidization area(m2) | Installed power(KW) | Steam pressure(Mpa) | Steam consumption(Kg/h) | Imported air temperature ℃ | External dimensions(L×W×H)mm | Cover an area(m2) |

| NLG2.0 | 2 | 50 | 0.2-1.0 | 400-1000 | 100-300 | 3000×1300×4500 | 45 |

| NLG2.5 | 2.5 | 65 | 600-1200 | 3500×1300×4500 | 55 | ||

| NLG3.0 | 3 | 85 | 1400-2200 | 3600×1400×4500 | 65 | ||

| NLG3.5 | 3.5 | 95 | 1000-2000 | 4000×1500×4500 | 80 | ||

| NLG4.0 | 4.0 | 110 | 1200-2000 | 4600×1600×5000 | 90 | ||

| NLG5.5 | 5.5 | 130 | 1400-2200 | 5000×1650×5000 | 100 | ||

| NLG6.0 | 6 | 140 | 1600-2800 | 6000×1700×5000 | 110 | ||

| NLG7.0 | 7 | 165 | 1800-3200 | 6600×1750×5000 | 120 | ||

| NLG8.0 | 8 | 170 | 2000-2800 | 7500×1800×5000 | 130 | ||

| NLG10 | 10 | 210 | 2400-3600 | 10000×1900×6500 | 140 | ||

| NLG15 | 15 | 300 | 3200-4400 | 15000×1900×6500 | 200 | ||

| NLG20 | 20 | 320 | 4000-6000 | 20000×2000×7000 | 240 |

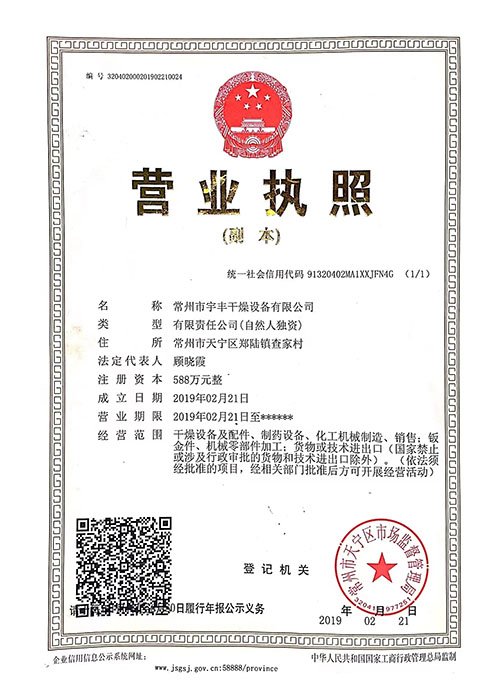

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13