Product Overview: The material enters the machine from the feeding port, and under the action of vibration force, it is thrown along the horizontal fluidized bed, continuously moving forward. The hot air passes through the fluidized bed and exchanges heat with the wet material. The wet air is removed by the cyclone separator and discharged from the exhaust port, while the dry material is discharged from the exhaust port.

Main purpose:

◆ Pharmaceutical and chemical industries: various tablet granules, boric acid, borax, hydroquinone, malic acid, maleic acid, etc.

◆ Food and building materials: wine troughs, monosodium glutamate, sugar, salt, slag, Douban, seeds, etc.

◆ It can also be used for material cooling, humidification, etc.

Working principle:

The material enters the machine from the feeding port, and under the action of vibration force, it is thrown along the horizontal fluidized bed, continuously moving forward. The hot air passes through the fluidized bed and exchanges heat with the wet material. The wet air is removed by the cyclone separator and discharged from the exhaust port, while the dry material is discharged from the exhaust port.

Product features:

● The material is heated evenly, with sufficient heat exchange and high drying intensity, saving about 30% energy compared to ordinary dryers.

● The vibration source is driven by a vibration motor, which runs smoothly, is easy to maintain, has low noise, and has a long service life.

● Fluidization is stable, with no dead corners or blowing through phenomena.

● Good adjustability, adaptable to a wide range of surfaces, the thickness of the material layer, and the speed of movement inside the machine can be infinitely adjusted with amplitude changes.

● Small surface damage to materials, suitable for drying fragile items, and does not affect work efficiency even when the particles are irregular.

● Adopting a fully enclosed structure effectively prevents cross contamination between materials and air, resulting in a clean working environment.

● When used for mass production of high moisture materials, multiple units can be connected in series to meet user requirements (typical materials: such as polyacrylamide, etc.).

Technical parameter table:

Model | A | B | C | D | E | F | Weight |

ZDG3×0.30 | 3000 | 300 | 1000 | 940 | 510 | 2020 | 1250kg |

ZDG4.5×0.30 | 4500 | 300 | 1000 | 940 | 510 | 2020 | 1560kg |

ZDG4.5×0.45 | 4500 | 450 | 1210 | 940 | 590 | 2100 | 1670kg |

ZDG4.5×0.60 | 4500 | 600 | 1360 | 940 | 660 | 2170 | 1910kg |

ZDG6×0.45 | 6000 | 450 | 1260 | 940 | 590 | 2100 | 2100kg |

ZDG6×0.60 | 6000 | 600 | 1410 | 940 | 660 | 2170 | 2410kg |

ZDG6×0.75 | 6000 | 750 | 1600 | 940 | 740 | 2250 | 2340kg |

ZDG6×0.9 | 6000 | 900 | 1750 | 940 | 810 | 2320 | 3160kg |

ZDG7.5×6.0 | 7500 | 600 | 1500 | 940 | 660 | 2170 | 3200kg |

ZDG7.5×0.75 | 7500 | 750 | 1660 | 940 | 740 | 2250 | 3600kg |

ZDG7.5×0.9 | 7500 | 900 | 1810 | 940 | 810 | 2320 | 4140kg |

ZDG7.5×1.2 | 7500 | 1200 | 2110 | 940 | 960 | 2470 | 5190kg |

| Model | Fluidized bed area m2 | Inlet air temperature ℃ | Air outlet temperature ℃ | Ability to evaporate water Kg/h | Vibration motor | |

| Model | Power KW | |||||

| ZDG3×0.30 | 0.9 | 70~140 | 40~70 | 20~35 | ZDG31-6 | 0.8×2 |

| ZDG4.5×0.30 | 1.35 | 35~50 | ZDG31-6 | 0.8×2 | ||

| ZDG4.5×0.45 | 2.025 | 50~70 | ZDG32-6 | 1.1×2 | ||

| ZDG4.5×0.60 | 2.7 | 70~90 | ZDG32-6 | 1.1×2 | ||

| ZDG6×0.45 | 2.7 | 80~100 | ZDG41-6 | 1.1×2 | ||

| ZDG6×0.60 | 3.6 | 100~130 | ZDG41-6 | 1.5×2 | ||

| ZDG6×0.75 | 4.5 | 120~170 | ZDG42-6 | 1.5×2 | ||

| ZDG6×0.9 | 5.4 | 140~170 | ZDG42-6 | 2.2×2 | ||

| ZDG7.5×0.6 | 4.5 | 130~150 | ZDG42-6 | 2.2×2 | ||

| ZDG7.5×0.75 | 5.625 | 150~180 | ZDG51-6 | 3.0×2 | ||

| ZDG7.5×0.9 | 6.75 | 160~210 | ZDG51-6 | 3.0×2 | ||

| ZDG7.5×1.2 | 9.0 | 200~280 | ZDG51-6 | 3.7×2 | ||

| ZDG7.5×1.5 | 11.25 | 230~330 | ZDG50-6 | 3.7×2 | ||

| ZDG8×1.8 | 14.4 | 290~420 | ZDG75-6 | 5.5×2 | ||

Note: Some parameters may be adjusted according to different materials during design, and the design shall prevail.

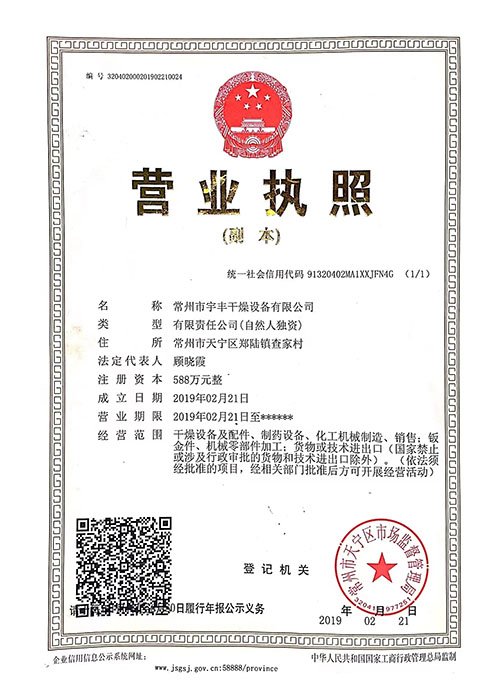

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13