Brief description: spray drying is a widely used process in liquid process forming and drying industry

Brief description: spray drying is a widely used process in liquid process forming and drying industry

Category: spray dryer

Detailed description:

overview:

Spray drying is widely used in liquid forming and drying industries. It is suitable for generating powder and granular solid products from solution, lotion, suspension and paste liquid raw materials. Therefore, when the particle size distribution, residual moisture content, bulk density and particle shape of the finished product need to meet accurate standards, spray drying is a very ideal process.

Principle:

After filtering and heating, the air enters the top air distributor of the dryer, and the hot air enters the drying chamber uniformly in a spiral shape. The feed liquid passes through the high-speed centrifugal atomizer at the top of the tower body, and (rotating) spray into extremely fine droplets, which flow in parallel with hot air and can be dried into finished products in a very short time. The finished product is continuously output from the bottom of the drying tower and the cyclone separator, and the exhaust gas is discharged by the fan.

Feature:

● The drying speed is fast, and after atomization, the surface area of the material liquid is greatly increased. In the hot air flow, 95% -98% of the water can be evaporated instantly, and the drying time is only a few seconds. It is particularly suitable for drying heat sensitive materials.

● The product has good uniformity, fluidity, solubility, high purity, and good quality.

● The production process is simplified and the operation control is convenient. For liquids with a moisture content of 40-60% (up to 90% for special materials), they can be dried into powder products in one go without the need for crushing and screening, reducing production processes and improving product purity. The particle size, bulk density, and moisture content of the product can be adjusted within a certain range by changing the operating conditions, making control and management very convenient.

Technical parameter table

Project/Parameters | Model:LPG | |||||

5 | 25 | 50 | 100 | 150 | 200-2000 | |

Inlet temperature℃ | 140~350 self-control | |||||

Outlet temperature℃ | ~80-90 | |||||

Water evaporation rate kg/h | 5 | 25 | 50 | 100 | 150 | 200-2000 |

Rotating form of centrifugal spray head | Compressed air transmission | Mechanical drive | ||||

Rotational speed(r.p.m) | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

Spray disc diameter(mm) | 50 | 100 | 120 | 140 | 150 | 180-340 |

Heat source | Electricity | Electricity+Steam | Electricity+steam, fuel oil, gas | Solved by users themselves | ||

Electric-heating power KW | 9 | 36 | 63 | 81 | 99 | |

L×W×H(m) | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.7×3.2×5.1 | 4.6×4.2×6 | 5.5×4.5×7 | Determine based on specific circumstances |

Dry powder recovery rate % | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 |

Note: Some parameters may be adjusted according to different materials during design, and the design shall prevail.

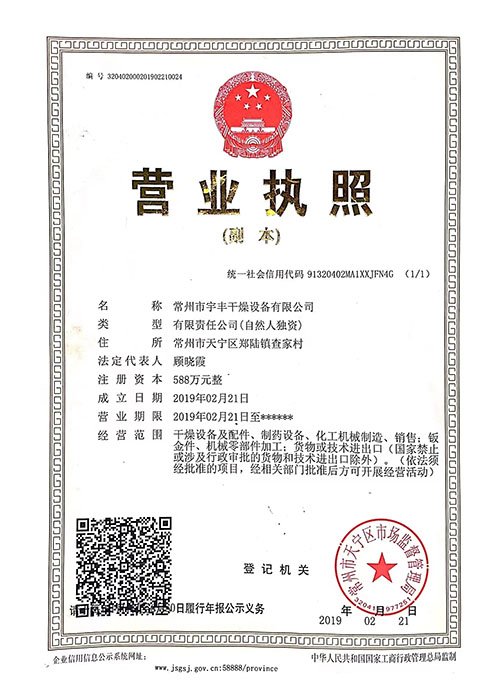

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13