Product Overview: Description: After the wet material is fed into one end of the dryer, it is evenly distributed and dispersed inside the dryer under the flipping of the inner cylinder's evenly distributed plate readerCategory: Drum dryerDetailed description: Overview:After being fed into one end of the dryer, t

Description: After the wet material is fed into one end of the dryer, it is evenly distributed and dispersed inside the dryer under the flipping of the inner cylinder's evenly distributed plate reader

Category: Drum dryer

Detailed description:

Overview:

After being fed into one end of the dryer, the wet material is evenly distributed and dispersed inside the dryer by flipping the plate reader evenly distributed in the inner cylinder. It also comes into full contact with the hot air flowing in parallel (counter current), accelerating the driving force of drying and mass transfer. During the drying process, the material can be controlled to move to the star shaped discharge valve at the other end of the dryer to discharge the finished product under the action of the inclined plate and hot air flow.

Application:

● In industries such as chemical, mining, and metallurgy, large particles with high specific gravity are dried, such as ores, blast furnace slag, coal, metal powders, phosphate fertilizers, and ammonium sulfate.

● Drying of powder and granular materials with special requirements, such as HP foaming agent, distiller's residue, light calcium carbonate, activated clay, magnetic powder, graphite, and slag.

● Materials that require low-temperature drying and require continuous drying in large quantities.

Feature:

● The rotary dryer has a high degree of mechanization and a large production capacity.

● The fluid has low resistance and low functional consumption when passing through the cylinder.

● Has strong adaptability to material characteristics.

● Stable operation, low operating costs, and good uniformity of product drying.

Technical parameter table:

Model | Direct heating downstream type | Direct heating counter current type | Composite heating | |||

Material type | Ore | HP foaming agent | Blast furnace slag | Ammonium sulfate | Phosphate fertilizer | Coal |

Processing capacity kg/h | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

Initial moisture content % | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

Final moisture content % | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

Average particle size mm | 6.5 | 0.05 | 4.7 | 0.5-0.7 | 0.5 | 5 |

Heavy accumulation of materials kg/m2 | 770 | 800 | 1890 | 1100 | 1500 | 750 |

Hot air intensity m3/kg | 39000 | 5400 | 10750 | 9800 | 6500 | 16000 |

Inlet gas temperature ℃ | 600 | 165 | 500 | 180 | 650 | 570 |

Material outlet temperature ℃ | 42 | 100 | 70 | 80 | 75 | |

Heating method | Coal | Steam electric heating | Heavy oil | JRF | Heavy oil | Heavy oil |

Loading coefficient | 6.3 | 7 | 7.5 | 7.8 | 18 | |

Rotational speed r.p.m | 4 | 4 | 3.5 | 3 | 4 | 2 |

Tilt m/m | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

Number of copied boards | 12 | 24 | 12 | 22 | Outside the inner cylinder 8 | Outside the inner cylinder 6 |

Diameter of dryer m | 2.0 | 1.5 | 2 | 2.3 | Outer cylinder 2 | Outer cylinder 2.4 |

Drying machine length m | 20 | 12 | 17 | 15 | 10 | 16 |

Drive power kw | 22 | 7.5 | 15 | 11 | 11 | 15 |

Note: Some parameters may be adjusted according to different materials during design, and the design shall prevail.

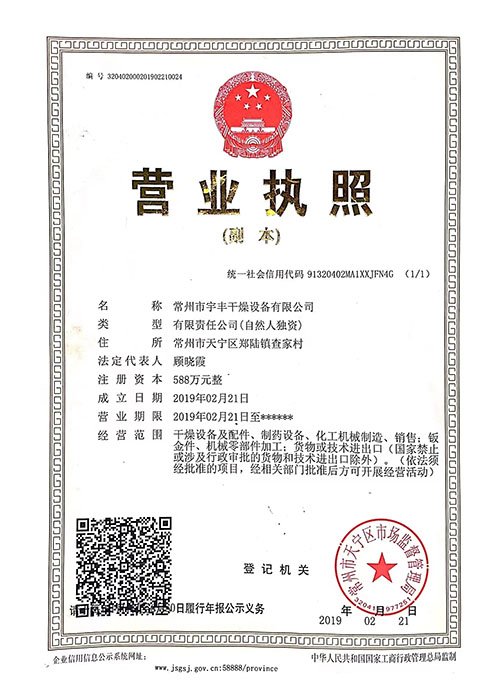

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13