Product Overview: The drum scraper dryer is an internally heated conductive rotary continuous drying equipment.The rotating drum adheres to a thick film through its lower chute, and heat is transported to the inner wall of the drum through pipes, conducted to the outer wall of the drum, and then transmitted to the fi

The drum scraper dryer is an internally heated conductive rotary continuous drying equipment.

The rotating drum adheres to a thick film through its lower chute, and heat is transported to the inner wall of the drum through pipes, conducted to the outer wall of the drum, and then transmitted to the film, causing the humidity in the film to evaporate and dehumidify, and drying the material containing moisture.

The dried material is removed from the drum by a scraper installed on the surface of the drum, and then transported to a screw conveyor placed below the scraper. The dry material is then collected and packaged by the screw conveyor.

Product Features

● High drying rate: Due to the thin film and consistent direction of heat and mass transfer, the surface of the film can maintain a drying rate of 30-70 kg The vaporization intensity of 30-70kg..H2O(m².h);

● High operational flexibility: wide adaptability, able to meet the requirements of various materials and different production volumes;

● High thermal efficiency: Its general thermal efficiency is between 80-90%;

● Short drying time: The drying cycle of materials is generally only 10-300 seconds, which is suitable for heat sensitive materials. If the drum dryer is set in a vacuum chamber, it can operate under reduced pressure conditions.

Product principle

Allow liquid or slurry like materials to form a thin film on the surface of a drum heated by steam or other heat carriers. The drum is dried during its rotation, and the product is scraped off with a scraper. The exposed surface of the drum comes into contact with the raw material again and forms a thin film for drying.

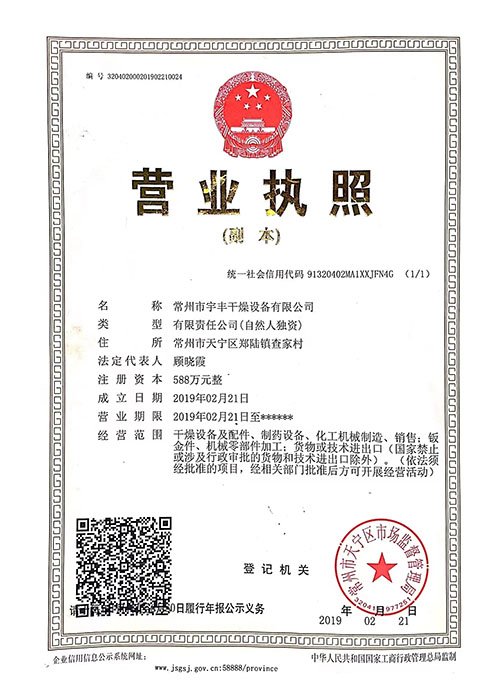

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13