Product Overview: (1) Product Overview:FD vacuum freeze-drying is currently a relatively common method for material dehydration. This technology freezes water containing substances at low temperatures, and then directly sublimates the water in a vacuum state, and uses condensation to capture the sublimated water vapo

(1) Product Overview:

FD vacuum freeze-drying is currently a relatively common method for material dehydration. This technology freezes water containing substances at low temperatures, and then directly sublimates the water in a vacuum state, and uses condensation to capture the sublimated water vapor, achieving the purpose of material dehydration and drying.

The physical, chemical, and biological states of the substance after FD vacuum freeze-drying remain basically unchanged, and the loss of volatile components and thermally denatured nutrients in the substance is minimal. The freeze-dried substance is porous, and its volume is basically the same as before drying. After adding water, due to the large contact area, it can quickly recover and have a longer storage period in a sealed container.

FD vacuum freeze dryer is widely used in the research and production of various thermosensitive biological products. Such as vaccines, drugs, vegetable vacuum packaging, snake powder, fish and turtle capsule pills, etc.

With the development of the biopharmaceutical and health industry, as well as the food and health products industry, vacuum freeze dryers have become equipment for the pharmaceutical, food, and health products industries and research institutions.

(2) Product features:

The drying vacuum freeze dryer is a new product designed for the renovation and upgrading of existing conventional vacuum drying and drying ovens, mastering core technologies. It is manufactured using the principle of vacuum drying, with a compact and reasonable structure, convenient maintenance, fully automatic control, and easy operation; Compared with conventional vacuum drying and oven drying at the same material heating temperature:

1.Has fast drying speed and reduces time by 3-10 times;

2.Low energy consumption, only 20% -30% of the energy consumption of ordinary dryers;

3.Wide drying temperature range (-55 ℃~120 ℃), capable of rapid drying in low temperature range (-20 ℃~50 ℃);

4.The vacuum in the drying chamber is oxygen free, and the drying quality can be comparable to the quality of fresh raw materials;

5.It can recycle organic solvents, which is beneficial for reducing production costs and is particularly suitable for materials containing organic solvents that cannot be dried by ordinary dryers.

6.Vertical open door structure, capable of in-situ freeze-drying of materials;

7.The control system is centered around PLC and uses a touch screen as the human-machine interface. It records real-time temperature data from multiple channels during the freeze-drying process and can be browsed in curve form. The human-machine interface is clear and intuitive.

8.Pre set shelf temperature control curve to achieve automation of sublimation process.

9.The host is equipped with a USB interface, which allows real-time uploading of freeze-dried data to the computer and enables functions such as saving, browsing, and printing.

(3) Application scope:

Food industry: Vacuum freeze-drying technology can be used for drying fruits, vegetables, meat and poultry, aquatic products, seasonings, convenience foods, and famous specialty products. It can achieve the goal of maintaining the original color, aroma, taste, shape, and freshness of food, and has good rehydration properties. The finished products are easy to store and transport, reduce costs, and extend shelf life.

Nutrition and health care: In dried royal jelly, ginseng, turtles, soft shelled turtles, earthworms and other nutritional and health products, vacuum freeze-drying technology is used to make people believe that the nutritional products are pure and natural.

Pharmaceutical industry: Vacuum freeze-drying can be applied to the dehydration and preservation of traditional Chinese and Western medicines such as serum, plasma, enzymes, antibiotics, hormones, etc. Biological research: Using vacuum freeze-drying technology to preserve blood, bacteria, arteries, bones, skin, cornea, nerve tissue, and various organs for a long time, they can be regenerated with only water supply during use, while still maintaining their biophysical properties.

Other applications include the production of aerospace insulation ceramics, preservation of wooden and silk products in archaeology, specimen making, and preparation of special materials, which can achieve unique effects.

(4) Product specifications and performance

| Model | FD-0.5C | FD-1C | FD-5C | FD-10C | FD-20C |

| Controlling party | HMI | HMI | HMI | PLC+ | PLC+ |

| Working party | Quick freezing, freeze-drying | Quick freezing, freeze-drying | Freeze drying (quick freezing) | Freeze drying (quick freezing) | Freeze drying (quick freezing) |

| Box material | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| Dry area (square) | 0.5 | 1 | 5 | 10 | 20 |

| Charge( kg ) | 5 | 10 | 50 | 100 | 200 |

| Tray size mm | 300/400/25 | 300/800/25 | 600/800/25 | 600/1000/25 | 600/1000/25 |

| Number of material trays | 5 | 7 | 12 | 17 | 34 |

| Form of material tray | Stainless steel disk or mesh disk | Stainless steel disk or mesh disk | Stainless steel disk or mesh disk | Stainless steel disk or mesh disk | Stainless steel disk or mesh disk |

| Number of shelves (pieces) | 6, | 8 | 13 | 18 | 36 |

| Shelf temperature(℃) | -55~120 | -55~120 | -55~120 | -55~120 | -55~120 |

| Shelf medium | Low temperature silicone oil | Low temperature silicone oil | Low temperature silicone oil | Low temperature silicone oil | Low temperature silicone oil |

| Drainage capacity 12 hours( kg ) | 5 | 10 | 50 | 100 | 200 |

| Vacuum pump | Rotary vane pump | Rotary vane pump | Rotary vane pump | Rotary vane pump | Rotary vane pump |

| Working vacuum | ≤130Pa | ≤130Pa | ≤130Pa | ≤130Pa | ≤130Pa |

| Vacuum | < 10Pa | < 10Pa | < 10Pa | < 10Pa | < 10Pa |

| Defrosting method | Hot water spray | Hot water spray | Hot water spray | Hot water spray | Hot water spray |

| Compressor | Imported fully enclosed | Imported fully enclosed | Grain wheel semi closed | Grain wheel semi closed | Grain wheel semi closed |

| Steam, air pressure pumps, etc | NOT REQUIRED | NOT REQUIRED | NOT REQUIRED | NOT REQUIRED | NOT REQUIRED |

| Energy | Single or three-phase electricity | Single or three-phase electricity | Three-phase electricity | Three-phase electricity | Three-phase electricity |

| Ambient Temperature | ≤ 40 ℃ | ≤ 40 ℃ | ≤40℃ | ≤ 40 ℃ | ≤ 40 ℃ |

| rated power | 5kw | 6kw | 16kw | 28kw | 45kw |

| Working dimensions: length * width * height | 1300x700x1700 | 1300x700x1700 | 3000x1500x1800 | 3200x1600x2000 | 5000x2200x2500 |

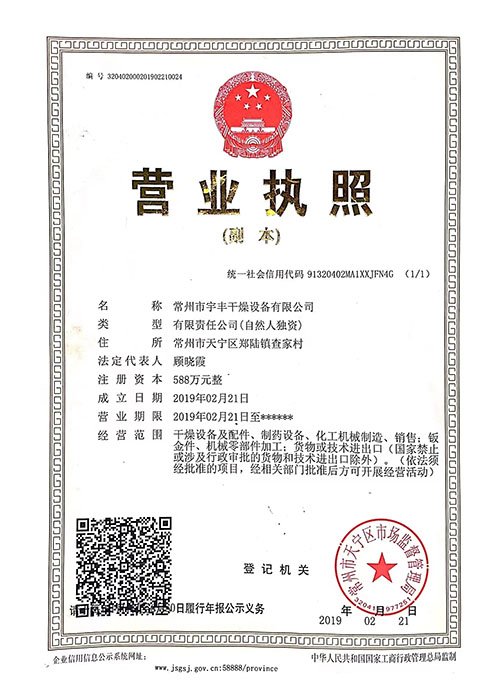

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13