Product Overview: Description: After being heated and purified, the air is introduced from the bottom by the induced draft fan and passes through the hole plate of the hopperCategory: Boiling Drying MachineDetailed description:Principle:After being heated and purified, the air is introduced from the bottom by the ind

Description: After being heated and purified, the air is introduced from the bottom by the induced draft fan and passes through the hole plate of the hopper

Description: After being heated and purified, the air is introduced from the bottom by the induced draft fan and passes through the hole plate of the hopper

Category: Boiling Drying Machine

Detailed description:

Principle:

After being heated and purified, the air is introduced from the bottom by the induced draft fan and passes through the hole plate of the hopper. In the studio, fluidization is formed through stirring and negative pressure, and the water evaporates rapidly and is carried away by the exhaust, resulting in rapid drying of the material.

Application:

● Mechanical screw extrusion granules, swinging granules, wet high-speed mixed granulation granules.

● Drying of wet granules and powdered materials in the fields of medicine, food, feed, chemical engineering, etc.

● Large particles, small pieces, sticky block granular materials.

● Materials such as konjac and polyacrylamide that undergo volume changes during drying.

Characteristic:

Characteristic:

● The fluidized bed has a circular structure to avoid dead corners.

● The hopper is set with mixing to avoid the aggregation of wet materials and the formation of channel flow during drying.

● Adopting the method of tipping and dumping materials, it is convenient, fast, and thorough, and an automatic feeding and discharging system can also be designed according to requirements.

● Sealed negative pressure operation, gas is filtered. Easy to operate and clean, it is an ideal equipment that meets GMP requirements.

● The drying speed is fast, the temperature is uniform, and the drying time for each batch is generally 20-30 minutes.

Technical parameter table

Project | Unit | Model | |||||||

Feeding | kg | 60 | 100 | 120 | 150 | 200 | 300 | 500 | |

Fan | Air volume | m3/h | 2361 | 3488 | 4000 | 4901 | 6032 | 7800 | 10800 |

Wind pressure | mmH2O | 594 | 533 | 533 | 679 | 787 | 950 | 950 | |

Power | kw | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 45 | |

Stirring power | kw | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 1.5 | 2.2 | |

Stirring speed | r.p.m | 11 | |||||||

Steam consumption | kg/h | 141 | 170 | 170 | 240 | 282 | 366 | 451 | |

Operating time | min | 15-30(Depending on the material situation) | |||||||

Host height | Square | mm | 2750 | 2850 | 2850 | 2900 | 3100 | 3300 | 3650 |

Circle | mm | 2700 | 2900 | 2900 | 2900 | 3100 | 3600 | 3850 | |

Note: Some parameters may be adjusted according to different materials during design, and the design shall prevail.

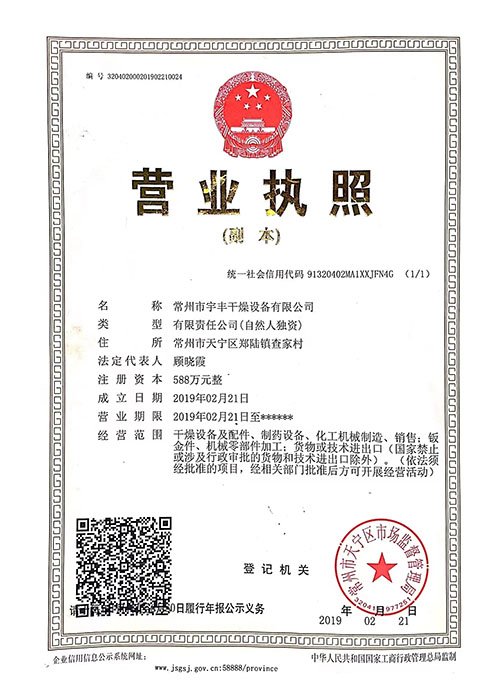

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13