Product Overview: Description: This machine is mainly suitable for drying powder or granular materials in industries such as pharmaceuticals, food, and chemicalsCategory: Boiling Drying MachineDetailed description:Application:This machine is mainly suitable for drying powder or granular materials in industries such a

Description: This machine is mainly suitable for drying powder or granular materials in industries such as pharmaceuticals, food, and chemicals

Description: This machine is mainly suitable for drying powder or granular materials in industries such as pharmaceuticals, food, and chemicals

Category: Boiling Drying Machine

Detailed description:

Application:

This machine is mainly suitable for drying powder or granular materials in industries such as pharmaceuticals, food, and chemicals.

Principle:

● Fluidized drying, fast heat and mass transfer;

● Operate under closed negative pressure without dust flying;

● Using anti-static filtering materials for safe operation;

● The equipment has no dead corners, thorough cleaning, and no cross contamination;

● Meet the requirements of GMP standards.

Technical parameter table:

Model | Unit | 3 | 5 | 30 | 60 | 120 | 200 | 300 | 500 | 1000 | |

Project | |||||||||||

Raw material container | Diameter | mm | 300 | 400 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | 2200 |

Volume | L | 12 | 22 | 100 | 220 | 420 | 670 | 1000 | 1500 | 2500 | |

Production capacity | Small | kg/batch | 1.5 | 4 | 15 | 30 | 80 | 100 | 150 | 250 | 500 |

Big | kg/batch | 4 | 6 | 36 | 72 | 140 | 240 | 360 | 600 | 1100 | |

Steam consumption | kg/batch | 12 | 23 | 70 | 140 | 211 | 282 | 366 | 465 | 800 | |

Air supply | M3/min | 0.3 | 0.3 | 0.3 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 1.5 | |

Fan power | kw | 2.2 | 4 | 5.5 | 11 | 18.5 | 22 | 30 | 45 | 75 | |

Temperature | ℃ | Automatic adjustment from room temperature to 120 ℃ | |||||||||

Material yield | % | >99 | |||||||||

Operating time | min | 15~30(Depending on the specific material) | |||||||||

Final moisture content | % | ~0.2(Depending on the specific material) | |||||||||

Noise | dB | ≤75 | |||||||||

Host height | mm | 2100 | 2300 | 2500 | 3000 | 3300 | 3800 | 4000 | 4800 | 6200 | |

Note: Some parameters may be adjusted according to different materials during design, and the design shall prevail.

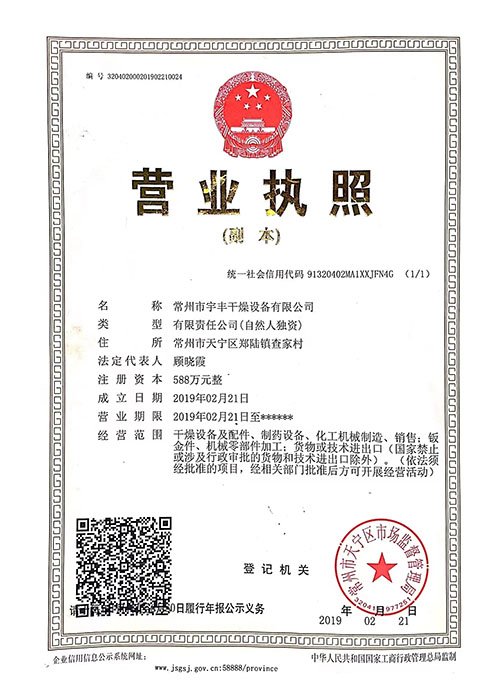

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13