Product Overview: Summary: Compared with the QG series pulse airflow, it has the advantages of longer material residence time and lower final moisture content of the product, which expands the range of material processingCategory: Airflow dryerDetailed description: Principle:Compared with the QG series pulse airflow,

Summary: Compared with the QG series pulse airflow, it has the advantages of longer material residence time and lower final moisture content of the product, which expands the range of material processing

Category: Airflow dryer

Detailed description:

Principle:

Compared with the QG series pulse airflow, it has the advantages of longer material residence time and lower final moisture content of the product, expanding the range of material processing.

The bottom enhancer has a unique design, with diamond shaped stirring teeth that achieve low airflow resistance. It is located inside a conical hopper and features both moving and fixed blades, resulting in significant crushing effects. The falling agglomerated material is quickly crushed into powder particles suitable for airflow drying. Another main function of stirring is to disperse the material, increasing the contact area with the high-speed hot air coming in from below the hopper. As a result, a fluidized bed with strong heat and mass transfer is formed in the hopper area, and most of the moisture is dried in the hopper area. As the drying process progresses, the lighter and finer dry material is significantly affected by the airflow, rising together with the airflow and further drying, and then coming out from the top of the drying tower into the material collection system.

Suitable materials:

This machine is particularly suitable for processing wet materials with high moisture content in paste like form, as well as materials that cannot be dried by other airflow drying methods. It is suitable for filter cakes, paste like products with certain viscosity, and products that require powder as the final product.

Technical parameter table:

Model | Evaporate water kgH2O/h | Installed power kw | Cover an area m2 | Main tower height m |

QFF-50 | 50 | 12 | 16 | 11 |

QFF-100 | 100 | 25 | 26 | 13 |

QFF-200 | 200 | 44.5 | 35 | 16 |

QFF-250 | 250 | 53.5 | 51 | 18 |

QFF-500 | 500 | 67.5 | 78 | 19 |

QFF-1000 | 1000 | 150 | 105 | 22 |

QFF-1500 | 1500 | 183 | 120 | 23 |

Note: 1. Water evaporation rate refers to the amount of water evaporated per hour at an inlet temperature of 180 ℃ and an outlet temperature of 80 ℃; 2. In addition to the above models, special designs can be made for users. 3. The above installed capacity is the standard matching, and the power may vary according to different materials.

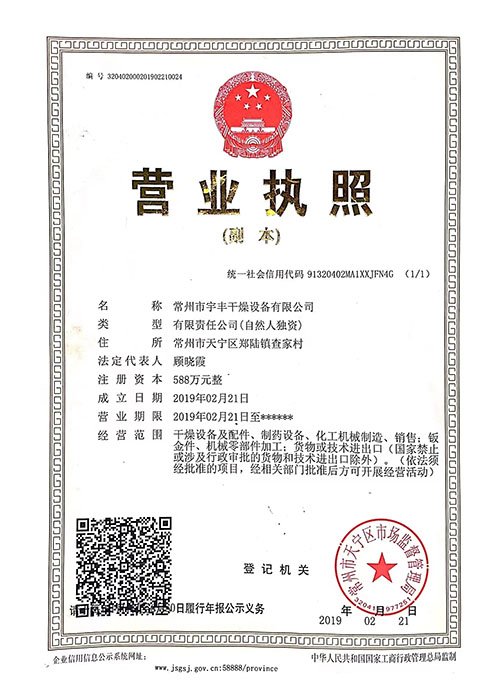

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13