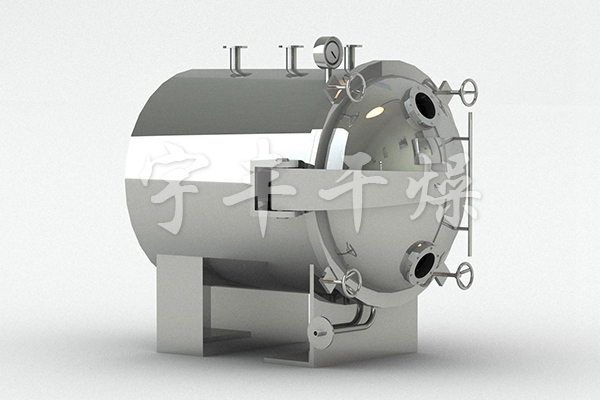

Product Overview: Summary: The boiling point of the material solution decreases under vacuum, which increases the heat transfer driving force of the evaporatorCategory: Vacuum drying machineSquare Detailed Description:Circular Detailed Description:Characteristic:●The boiling point of the material solution decr

Summary: The boiling point of the material solution decreases under vacuum, which increases the heat transfer driving force of the evaporator

Category: Vacuum drying machine

Square Detailed Description:

Circular Detailed Description:

Characteristic:

Characteristic:

Technical parameter table

Specifications | YZG-600 | YZG-800 | YZG-1000 | YZG-1400A | FZG-10 | FZG-15 | FZG-20 |

Size inside the drying oven(mm) | φ600×976 | φ800×1247 | φ1000×1527 | φ1400×2054 | 1500×1060×1220 | 1500×1400×1220 | 1500×1800×1220 |

Outer dimensions of drying oven(mm) | 1135×810×1020 | 1700×1045×1335 | 1693×1190×1500 | 2380×1675×1920 | 1924×1720×1513 | 1513×1924×2060 | 1924×2500× 1513 |

Number of drying rack layers | 4 | 4 | 6 | 8 | 5 | 8 | 12 |

Interlayer distance(mm) | 81 | 82 | 102 | 102 | 122 | 122 | 122 |

Drying tray size(mm) | 310×600×45 | 520×410×45 | 520×410×45 | 460×640×45 | 460×640×45 | 460×640×45 | 460×640×45 |

Number of baking dishes | 4 | 8 | 12 | 32 | 20 | 32 | 48 |

Pressure inside the drying rack tube(MPa) | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 |

Drying rack operating temperature(℃) | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 |

Empty vacuum degree inside the box(MPa) | -0.1 | -0.1 | -0.1 | -0.1 | -0.1 | -0.1 | 0.1 |

At -0.1MPa, heating temperature 110 ℃, | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 |

When using a condenser, the vacuum pump model | 2X-1 2KW | 2X-30A 3KW | 2X-30A 3KW | 2X-70A 5.5KW | 2X-70A 5.5KW | 2X-70A 5.5KW | 2X-90A 2KW |

When not using a condenser, | SZ-0.5 1.5KW | SZ-1 2.2KW | SZ-1 2.2KW | SZ-1 2.2KW | SZ-2 4KW | SZ-2 4KW | SZ-2 5.5KW |

Weight of drying oven(kg) | 250 | 600 | 800 | 1400 | 1400 | 2100 | 3200 |

The above data. For the elderly only. If there are special requirements, our factory provides design and consulting services.

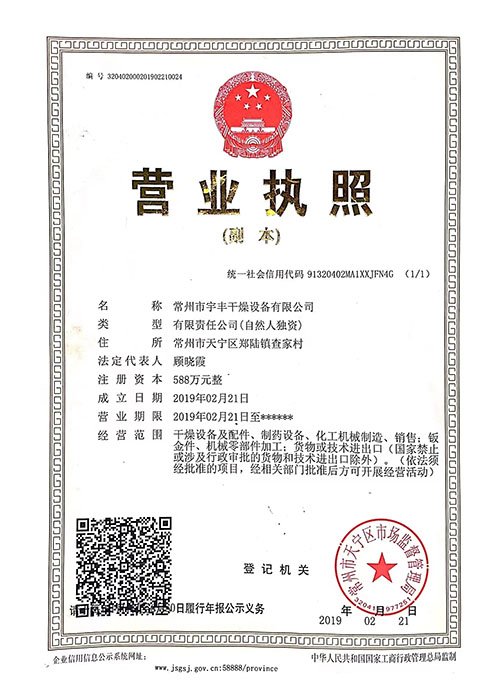

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13