Product Overview: Summary: SZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with similar domestic product technologiesCategory: Vacuum drying machineDetailed description:Overview:The SZG double cone vacuum dryer is a new generation drying device developed by our f

Summary: SZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with similar domestic product technologies

Category: Vacuum drying machine

Detailed description:

Overview:

Overview:

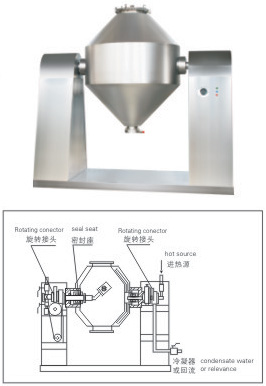

The SZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with similar domestic product technologies, SZG double cone vacuum has a two-stage elastic connection method of belt and chain, so the equipment runs smoothly. The specially designed tooling fully embodies the good concentricity of the two shafts, and the heat medium and vacuum system use reliable American technology rotary joints. On this basis, we have developed SZG-A, which can achieve both stepless speed regulation and constant temperature control. As a professional drying equipment manufacturer, we serve our customers with over a hundred units per year. Our products range from high-temperature heat transfer oil as the heat medium, medium temperature steam, and low-temperature hot water. When drying viscous materials, our factory will specially design a "copying plate" mechanism or set up ball bearings inside the tank for you.

Principle:

● Heat energy (such as hot water, low pressure, steam, or thermal oil) is introduced into a sealed interlayer, and the heat is transferred to the dry material through the inner shell.

● Under the power drive, the tank rotates slowly, and the materials inside the tank continuously mix, thereby achieving the purpose of enhancing drying.

● The material is in a vacuum state, and the decrease in vapor pressure causes the water (solvent) on the surface of the material to reach saturation and evaporate, which is promptly discharged and recovered by a vacuum pump. The moisture (solvent) inside the material continuously permeates, evaporates, and is discharged to the surface, and these three processes are carried out continuously, achieving the drying purpose of the material in a very short time.

Characteristic:

● When oil is heated, automatic constant temperature control is used to dry biochemical products and mineral raw materials, and the temperature can be between 20 and 160 ℃.

● High thermal efficiency, more than twice as high as a typical oven.

● Indirect heating ensures that the material is not contaminated and meets the requirements "GMP" requirement. The equipment maintenance operation is simple and easy to clean.

Application:

Suitable for the concentration, mixing, drying of powdered, granular, and fibrous materials in industries such as chemical, pharmaceutical, and food, as well as materials that require low-temperature drying (such as biochemical products). It is also more suitable for drying materials that are prone to oxidation, volatility, heat sensitivity, strong irritation, toxicity, and materials that do not allow crystal destruction.

Technical parameter table

Project | Unit | Model | ||||||||||

Name | Unit | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

Total Volume | L | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

Working volume | L | 50 | 100 | 175 | 250 | 375 | 500 | 750 | 1000 | 1500 | 2000 | 2500 |

Heating area | m2 | 1.16 | 1.5 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 10.2 | 12.1 | 14.1 |

Rotational speed | Rpm | 6 | 5 | 4 | 4 | 4 | ||||||

Power | Kw | 0.75 | 1.1 | 1.5 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 | 7.5 |

Rotation height | mm | 1810 | 1910 | 2090 | 2195 | 2500 | 2665 | 2915 | 3055 | 3530 | 3800 | 4180 |

Whole machine weight | kg | 825 | 1050 | 1350 | 1650 | 1800 | 2070 | 2250 | 3000 | 4500 | 5350 | 6000 |

Design pressure inside the tank | Mpa | -0.09~0.096 | ||||||||||

Interlayer design pressure | Mpa | 0.3 | ||||||||||

| The motor can be equipped with a variable speed motor according to user requirements, with a speed range of 0-6rpm The capacity of this machine can be designed to be 10000L | ||||||||||||

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13