Cone vacuum mixing dryer is a new type of equipment for powder drying in industries such as pharmaceuticals, chemicals, and food. The birth of this device effectively solves the shortcomings of traditional drying equipment, such as long working hours, low efficiency, loud noise, easy agglomeration, multiple leakage points, difficult maintenance, and inconvenient operation and cleaning. It is currently the most efficient drying equipment with the lowest unit energy consumption, highest efficiency, and best results among similar equipment used domestically and internationally in the industry. At the same time, the device has met FDA international standards and passed the acceptance smoothly.

(1)Product Features:

The final moisture content is particularly low

Solvent Recovery

(2)Equipment features:

1.The dust removal device of the single cone vacuum mixing dryer is installed above the container and connected to the vacuum suction pipe. During the drying process, it is not easy for materials that are flying to get stuck. The dust collector is equipped with a reverse blowing device, which can blow back the materials adsorbed in the dust collector at any time during the drying process, ensuring that the vacuum pumping pipeline is unobstructed.

2.The single cone vacuum mixing dryer has a simple overall structure, easy maintenance, convenient cleaning, and can achieve online cleaning or sterilization. And a computer self-control system can be configured according to customer needs. Accurate process control is achieved for each batch of materials.

(3)Application

Comparison Table of Single Cone Drying Machine and Traditional Drying Equipment Effectiveness (1000L)

Legacy devices | Single cone vacuum dryer | ||||||

Equipment name | Charge | Drying time | Material form (existing after drying) | Charge | Drying time | Material form (after drying) | Residual solution (or moisture) |

Double-cone dryer | 300 | >22 | Spherical lumps | 600 | 7 | Completely powdery | |

Double-cone dryer | 140 | 48 | Spherical lumps | 400 | 12 | Completely powdery | |

Double-cone dryer | 140 | 48 | Spherical lumps | 400 | 12 | Completely powdery | |

Disc oven | 290 | 48 | Block-shaped | 600 | 10 | Completely powdery | |

Disc oven | 290 | 19 | Block-shaped | 500 | 7 | Completely powdery | |

Double-cone dryer | 300 | 12 | Spherical lumps | 600 | 6 | Completely powdery | |

Double-cone dryer | 400 | 28 | Block-shaped | 650 | 8 | Completely powdery | |

Double-cone dryer | 400 | 22 | Block-shaped | 650 | 10 | Completely powdery | |

Multiple devices | 250 | >150 | Thick plate shape | 500 | 45 | Completely powdery | |

Oven→Double-cone dryer | 400 | >80 | Graininess | 450 | 8 | Completely powdery | |

Double-cone dryer | 440 | 22 | Block-shaped | 500 | 8 | Completely powdery | |

Multiple devices | 300 | 72 | Graininess | 500 | 27 | Completely powdery | |

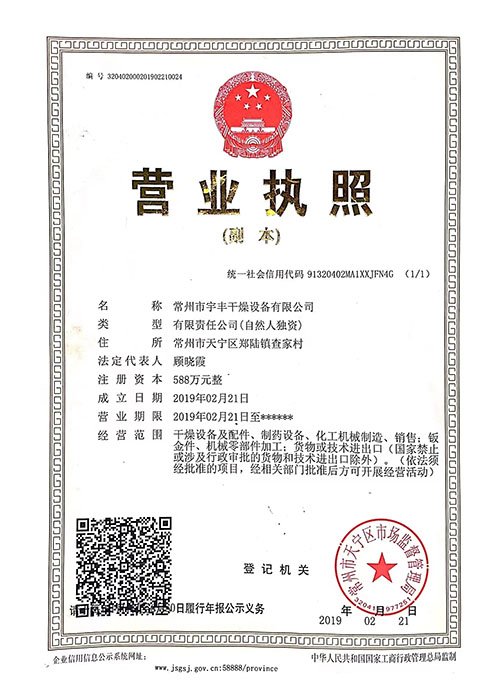

Changzhou Yufeng Drying Equipment Co., Ltd. (formerly Changzhou Huayue Drying Equipment Co., Ltd.) was founded in 2004. It is a well-known manufacturer specializing in the manufacturing of drying, mixing, crushing, granulation and other equipment. The company has achieved significant growth and improvement in terms of enterprise scale, production equipment, design level, employee quality, management ability, capital reserve, marketing strategy, annual performance, etc. The development space and potential of the enterprise are great. It is a backbone enterprise in the pharmaceutical, food, and chemical machinery industries in Jiangsu Province.

The company has been committed to the development and research of drying, mixing, granulation, crushing, concentration, nitrogen closed-loop circulation recovery of solvents, energy conservation and consumption reduction, high efficiency and environmental protection, intelligent control, and multi-functional machines. Its business covers many industries across the country, such as pharmaceuticals, chemicals, food, environmental protection, new materials, new energy, petrochemicals, medical, agricultural, pesticide, electronics, mining and other industries, with hundreds of varieties. It undertakes turnkey projects, general contracting projects, subcontracting projects, etc.

Maintenance of spray dryer

24.04.15How to reduce material loss in optimization of spr···

24.04.15Optimization and energy-saving technology of spray···

24.04.15How to optimize spray dryer for polymer synthesis

24.04.15What are the applications of spray dryer in chemic···

24.04.15Working principle of blade dryer

24.04.13What is the blade design of a blade dryer

24.04.13What are the application scenarios of blade dryer

24.04.13What materials is the blade dryer suitable for

24.04.13What safety precautions should be taken during the···

24.04.13